ELECTRIC INDUCTION FURNACE

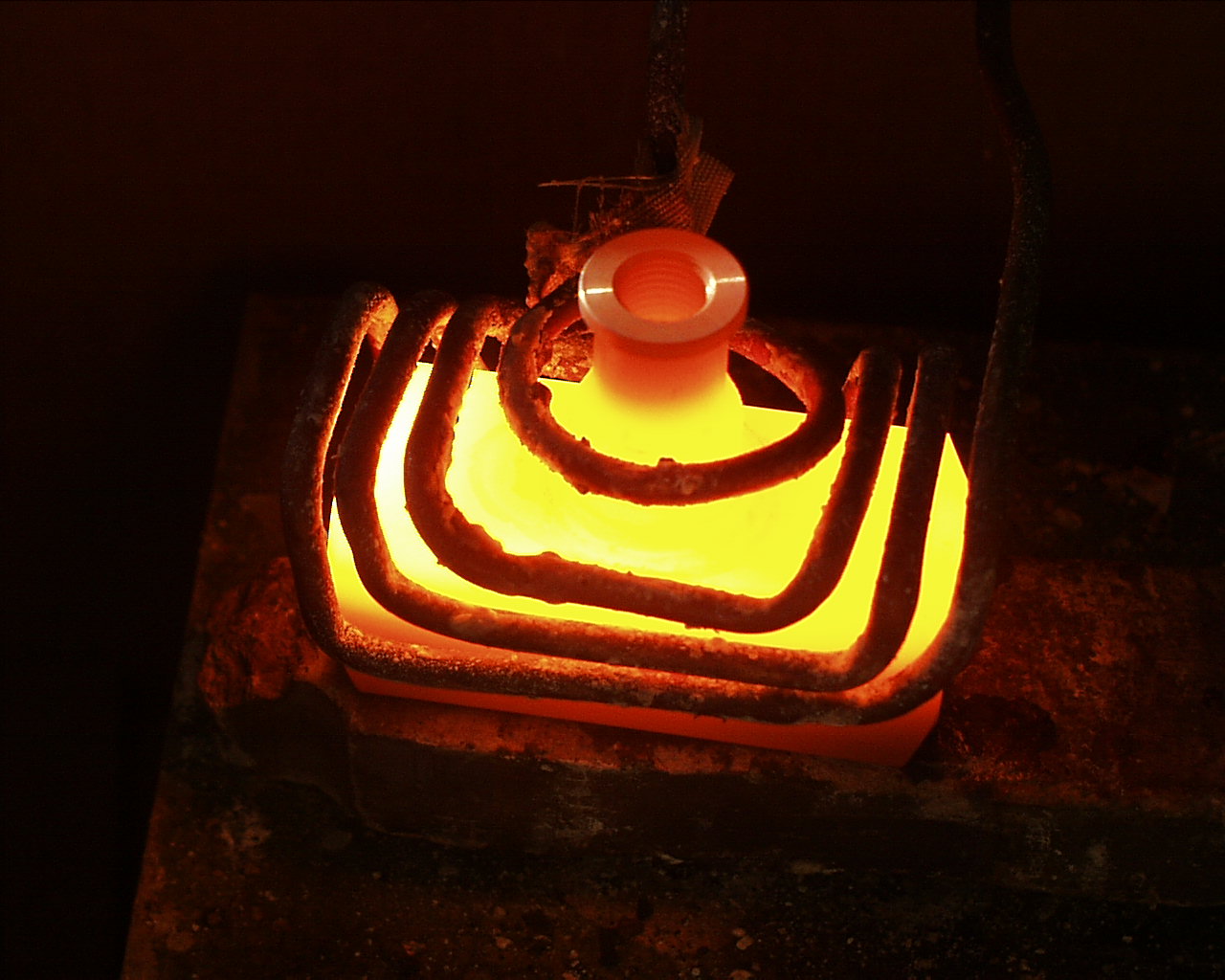

An Induction Furnace uses induction to heat a metal to its melting point which is based on the theory of Electro Magnetic Induction. Depending on their frequency (50 Hz 250 kHz) these can be divided to -. Advantages of Induction Furnace 1. It has no electrodes and electric arcs which allow productions of steel & alloys low in

The Advantages of Induction Furnace

Advantages of Induction Furnace High Efficiency and Speed High Quality and Mixing Ability Alloying Elements and Precious Metals Ferrous and Non-Ferrous Metals Induction Furnace Maintenance and Process Control Refractory Lining and Crucible Oxides and Charges Stirring Action and Strip Edges Vacuum and Gas Atmosphere Conclusion Induction Furnace

Characteristics and advantages of induction furnace heating Huaxin

Advantages and disadvantages of induction furnace; Induction stoves have many advantages, but there are also some limitations: advantage: High efficiency: The induction furnace can achieve high temperatures in a short time, so the heating speed is fast and the energy consumption is low.

The Advantages of Induction Furnace

Induction heating equipment requires an understanding of physics, electromagnetism, power electronics and process control, but the basic concepts behind induction heating are simple to understand.. A major advantage that is inherent with induction melting is inductive stirring. In an induction furnace, the metal charge material is melted or.

PPT Induction Heating PowerPoint Presentation, free download ID5476790

Pros Induction furnaces are commonly used in modern foundry, steel plants and mining industry. This is because Induction furnace is more efficient and melting process is clean. Induction also ensures a more controlled melting process as compared to other kinds of metal melting.

Advantages and Disadvantages of Induction Heating

Characteristics and application: The main advantage of induction heating: ① having overall heating workpiece deformation is small, small power consumption. The ② pollution. ③ heating speed, the workpiece surface oxidation and decarbonization lighter. ④ surface hardened layer can be adjusted as needed, easy to control.

INDUCTION FURNACE

Advantages of Induction Furnaces: The induction furnace principle has the following advantages compared with traditional heating methods: Energy efficiency: Induction furnaces are highly energy efficient because heat is generated directly inside the metal, minimizing heat loss.

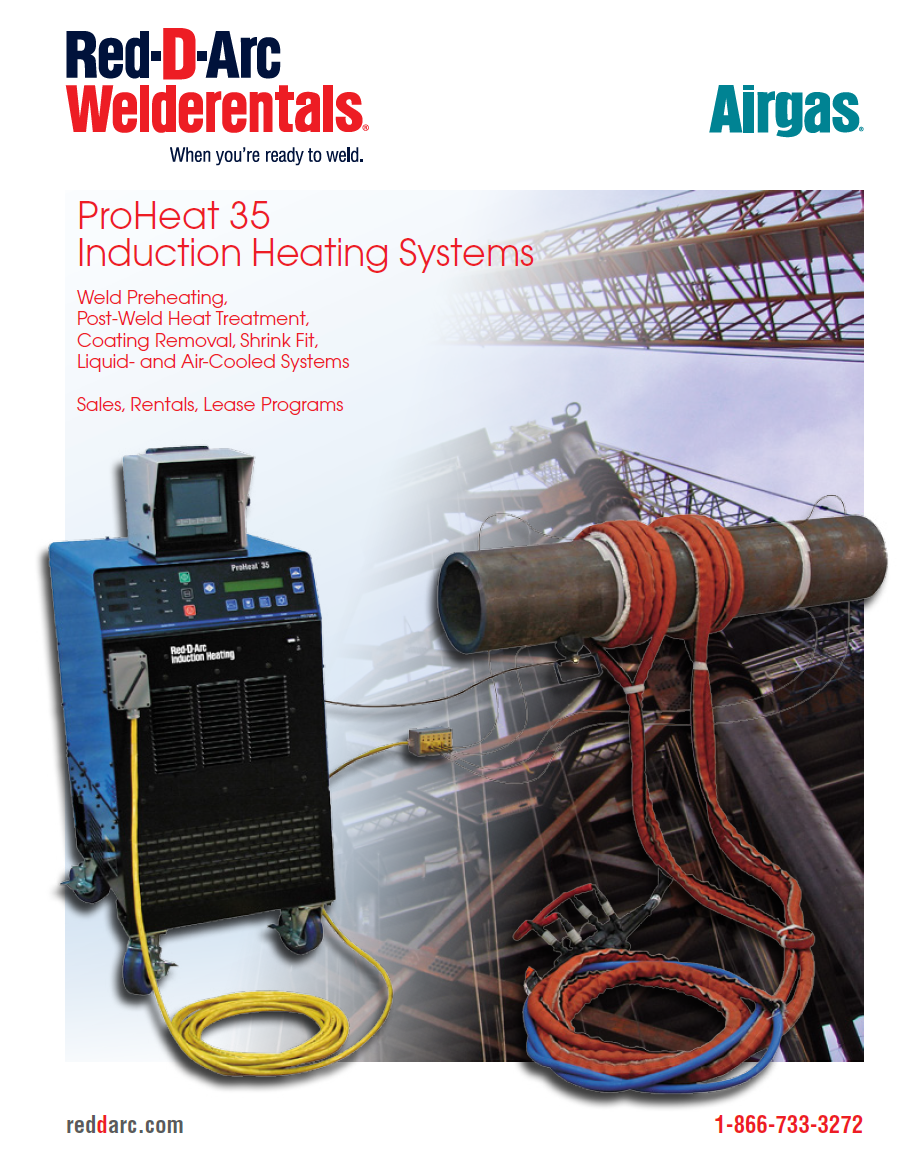

Top 5 Applications and Benefits of Induction Heating Machines RedD

In steel smelting, compared with electric arc furnace smelting, the use of crucible induction furnace has many advantages, such as: (1) Although the induction furnace is also a.

induction heating Why Choose Induction Heating and what are its advantages

An induction stove is a great way to improve your kitchen while saving money and reducing air pollution.. Induction stoves save a lot of energy compared to traditional heating methods, making them cheap to operate, and the lack of hot burners is also great from a safety perspective.. If you want the benefits without the upfront expenses.

The Advantages of an Induction Furnace to Melt Silver Precipitate

Induction cooktops almost sound magical—the stove heats up beneath pans but is cool to the touch, it boils water way faster than other ranges, and it's easy to clean. Plus, because it's.

Induction furnace for Bridgman method MGML.eu

Advantages of Induction Heating : The various advantages of induction heating are, It is suitable for periodic operations. The heating of material is carried out without making any direct contact with the power supply. There is no noise, dust, dirt, or smoke in its operation, thus the working conditions are pleasant.

PPT Discover The Advantages of Induction Heating Furnaces in India

The advantage of the induction furnace is a clean, energy-efficient and well-controlled melting process, compared to most other means of metal melting. Most modern foundries use this type of furnace, and many iron foundries are replacing cupola furnaces with induction furnaces to melt cast iron, as the former emit much dust and other pollutants.

Brass Induction Melting Furnace, Features & advantages

How does induction heating work and what are its applications? Find out in this comprehensive handbook that covers the theory, design, and practice of induction heating, with chapters on materials, equipment, modeling, and quality control. This handbook is part of Routledge Handbooks Online, a collection of authoritative and cutting-edge resources for researchers and students.

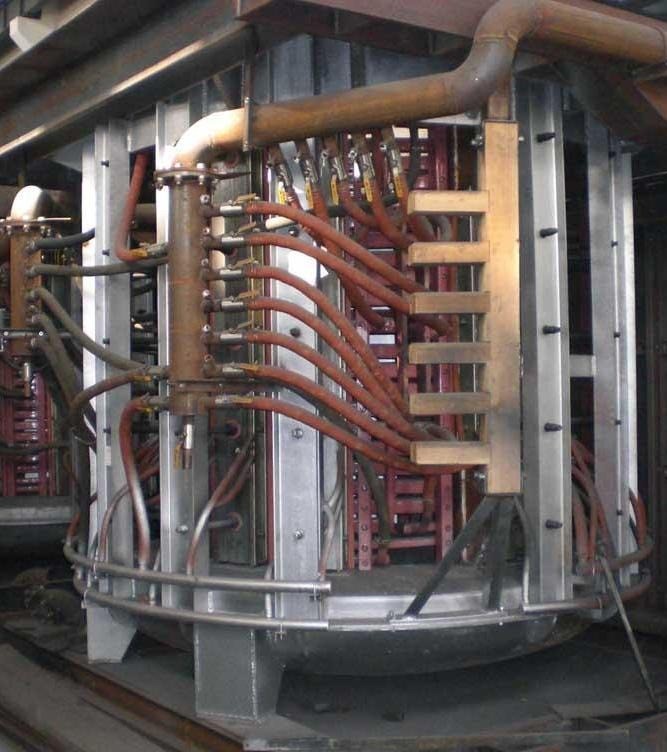

induction furnace components BlogMech

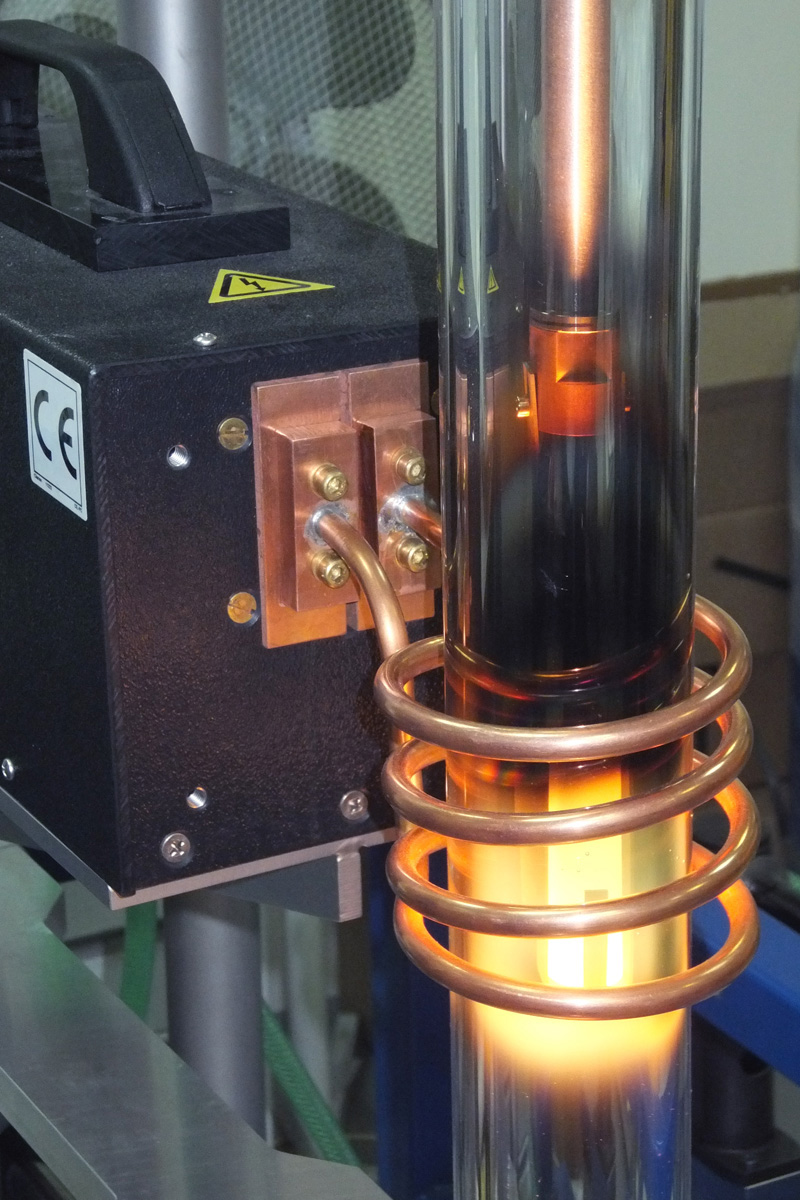

1. Direct Core Type Induction Furnace: Direct core type induction furnace is shown in Fig. 5.11 which consists of an iron core, crucible of some insulating material and primary winding connected to an ac supply. The charge is kept in the crucible, which forms a single turn short-circuited secondary circuit.

All About Induction Furnace What It Is and How It Works YouTube

Let's explore some of the key benefits: Efficiency: Induction heating is highly efficient as it generates heat directly within the workpiece, reducing energy wastage. Precision: The heating process is very precise, which is especially useful in industries requiring accurate temperature control.

coreless induction furnace 1 YouTube

An induction furnace works by transferring heat energy via a high-voltage primary coil that induces a high current, a low voltage, or a secondary coil. These types of furnaces are great for melting a wide array of metals while maintaining a low level of melt loss. There are two main varieties of these furnaces: coreless and channel.